Laser Cutting Services

Laser Cutting Services at MIMF

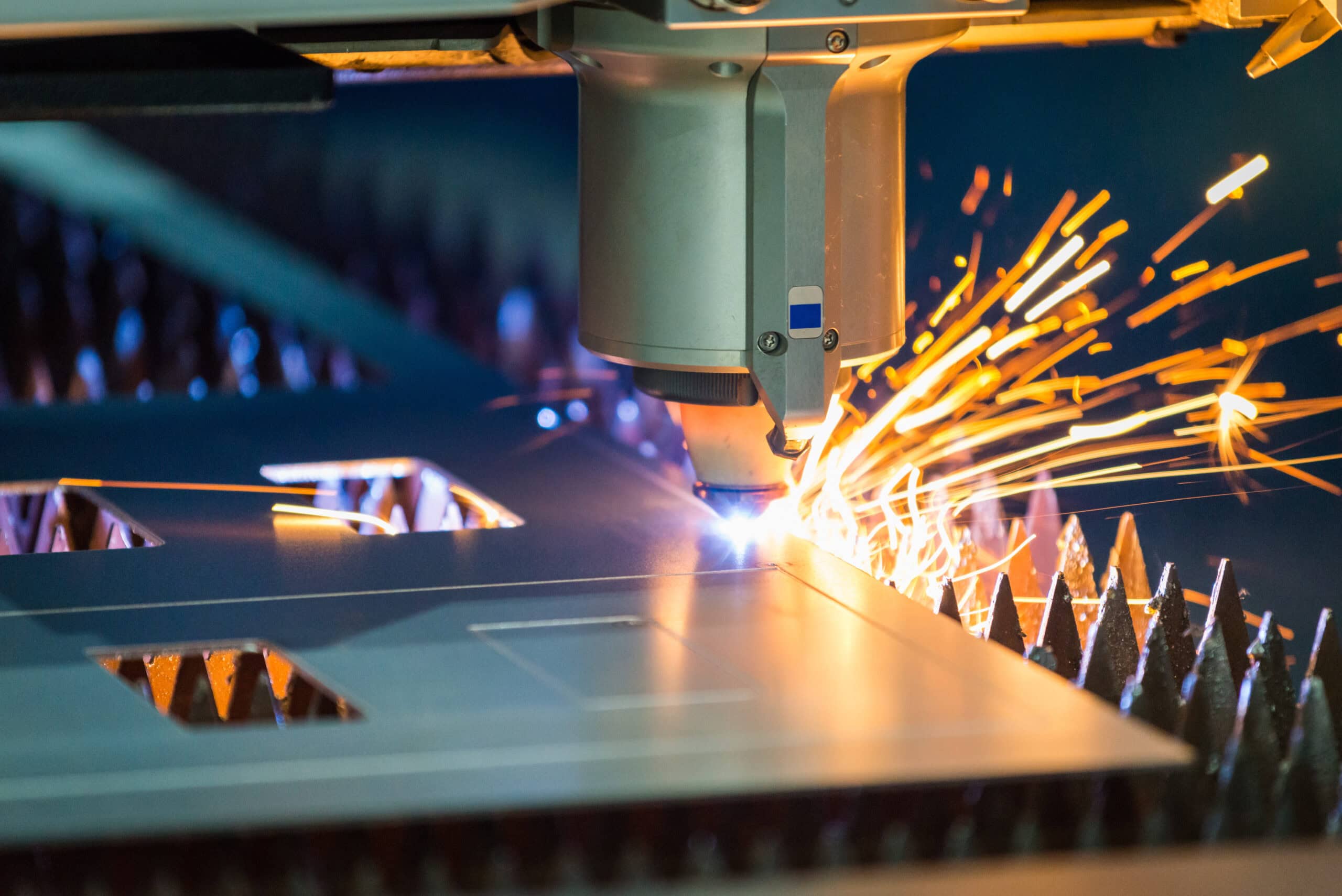

Especially used for sheets of metal, fiber optic laser cutting machines are known for their efficiency and ability to handle high-volume production. Fiber laser cutting technology is a major advancement in manufacturing, using a highly focused laser beam to cut metals with exceptional precision and speed. This also allows for intricate designs and high levels of accuracy to 0.005 of an inch with ability to compensate to 0.001 inch. The light is guided through a fiber optic cable and straightened by a lens that is hyper-focused on the metal.

This laser cutting method creates extremely accurate, smooth cuts and clean edges for several types of metals. The fiber optic laser cutter creates rapid processing speeds to foster fast lead times, especially due to high throughput. Fiber optic laser cutting has helped the manufacturing process by enabling the production of high-quality, precise parts more efficiently than traditional methods.

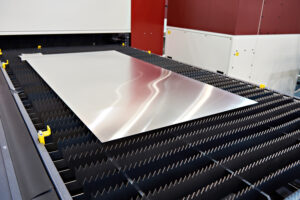

With intelligent design and simple operation, our 6kw, 5 ft X 10 ft Dual Shuttle Table Laser Cutter can produce hundreds of parts per day from various thicknesses of these common metals:

- Stainless Steel: up to 1/2 inch material thickness

- Carbon Steel: up to 5/8 inch material thickness

- Aluminum: up to 3/4 inch material thickness

Laser Cutting Precision & Accuracy

Uncompromising Accuracy: Fiber laser cutting boasts an incredible level of accuracy, achieving tolerances down to 0.005 of an inch, with the ability to compensate to an even finer 0.001 of an inch. This precision ensures that your parts meet the most stringent specifications, minimizing errors and rework.

Smooth Cuts, Minimal Post-Processing: The focused laser beam produces exceptionally smooth cuts, minimizing the need for secondary finishing operations. This saves you time and resources, reducing overall production costs.

Intricate Designs, Effortless Execution: The fine, highly focused laser beam enables the creation of complex and intricate designs with ease. Whether you require sharp corners, smooth curves, or intricate patterns, fiber laser cutting can bring your vision to life with exceptional detail.

Versatile Material Compatibility: Fiber laser cutting can handle a wide variety of metals, including steel, stainless steel, aluminum, copper, and brass, offering flexibility for diverse manufacturing needs. Different thicknesses can be accommodated with ease, expanding your production capabilities.

Consistent Quality, Every Time: The stability and controllability of the fiber laser beam guarantee consistent cut quality across the entire sheet, minimizing variations and ensuring that every part meets your exacting standards.

Contact us today to learn more about how our services can benefit your business.

How Fiber Laser Cutting Works

At the heart of this technology lies a highly focused laser beam, generated and amplified within a fiber optic cable. This beam, unlike traditional CO2 lasers, is delivered through a flexible fiber, allowing for greater efficiency and a smaller footprint. The light is then precisely directed and focused by a lens onto the material’s surface, delivering an intense concentration of energy. This energy rapidly heats and vaporizes the material, creating a clean, precise cut

Benefits of Laser Cutting Services

High-Volume Production, Seamlessly Managed: Fiber laser cutting machines are designed for high-volume production environments. Their rapid cutting speeds and automated material handling systems enable you to meet demanding production schedules and reduce lead times.

Faster Processing Speeds, Quicker Turnarounds: Compared to traditional cutting methods, fiber laser cutting significantly reduces processing times. This translates to faster turnaround times for your projects, allowing you to respond quickly to customer demands and stay ahead of the competition.

Optimized for Sheet Metal: While versatile, fiber laser cutting excels in processing sheet metal, a common material in numerous industries. Its speed and precision make it an ideal solution for manufacturing enclosures, panels, brackets, and other sheet metal components.

Metal Types for Laser Cutting Services

Your Trusted Partner for Laser Cutting Services

We understand that your manufacturing needs are unique. By leveraging the power of fiber optic laser cutting, we can partner with you to deliver:

Customized Solutions: We can tailor our services to meet your specific requirements, whether you need high-volume production runs or small, intricate parts.

Collaborative Design Support: Our experienced team can work with you to optimize your designs for laser cutting, ensuring the best possible results.

Fast and Reliable Service: We are committed to providing prompt and reliable service, meeting your deadlines and exceeding your expectations.

In addition to laser cutting services, MIMF will work on your project from A to Z. Come to us for custom parts or production runs from a wide range of industries. We pride ourselves on our experience and customer service.